Revolutionary machine learning technology

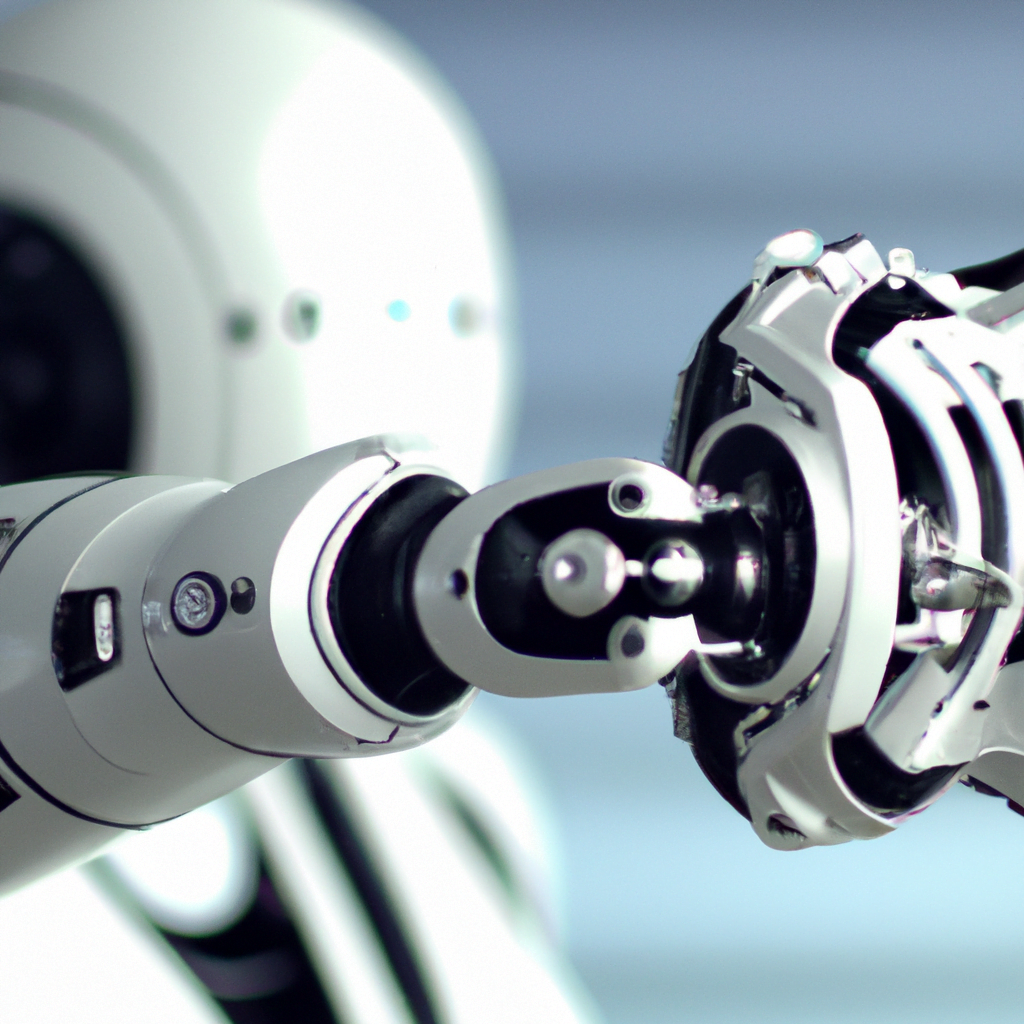

Mechanical systems that involve moving parts are vulnerable to damage due to friction. Researchers from Tohoku University have developed an AI-driven contact control system to reduce contact with damaged areas in these systems. Although currently tested in lab experiments, this technology could eventually lead to more efficient machinery.

Innovative Materials with “Morphing Surfaces”

The research is focused on the potential of innovative materials possessing “morphing surfaces” which can adapt to the environment they operate in. These materials are developed to mimic the flexibility found in living systems, such as leaf surfaces that change with variations in humidity. One example in engineering is a surface composed of a diaphragm supported by hard substrate, with changes in stress pressure altering the surface morphologies.

AI-Driven Contact Control System

The team developed an artificial intelligence procedure in which sensors analyze the friction between two surfaces. Once it detects where damage is occurring, the procedure can then use the “morphing” capacity of the surface to minimize the frictional contact with damaged regions. According to Professor Motoyuki Murashima, this is the first research in the world to use artificial intelligence to control the shape of morphing surfaces and successfully detect the position of damage on interacting surfaces.

Proof-of-Concept System and Future Development

The proof-of-concept system used disks spinning within a cylinder, and the researchers were able to achieve a steady reduction in fluctuated friction caused by contact between affected parts of the material under investigation. The next step is to move closer to situations in which the procedure could be applied to real engineering challenges, such as industrial machinery. The ultimate aim is to allow a wide range of machinery to operate with less routine wear and damage, achieving longer useful lifespans and cost savings due to less frequent part replacements.

Conclusion

The contact control system developed by Tohoku University researchers could shift the design strategy of mechanical systems away from the traditional approach of developing new and superior materials to developing surfaces that can actively adapt to reduce the damage. Professor Murashima suggests that more sophisticated learning and control algorithms are needed to reduce the time needed to learn the characteristics of the analyzed surfaces and achieve more refined and speedier control that prevents damage. The research is published in the journal Tribology International.